New fission designs will flow molten salt through the reactor core, where tritium will be developed from the lithium component of the molten salt. Tritium is dangerous because of its high activity and ease of diffusion through pipes, and it needs to be continually removed to prevent it from escaping into the environment. On the other hand, fusion systems need to renew their tritium fuel supply by producing it in a closed cycle in their reactor.

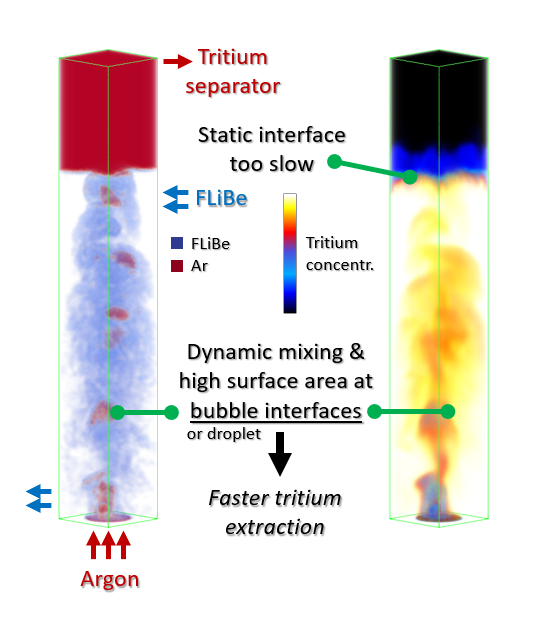

Tritium extraction is thus a universal challenge in advancing all types of nuclear power. The main proposed extractor concepts are membrane extractors (permeator-against-vacuum, or PAV), which use Group V metals such as vanadium or palladium with high hydrogen dissociation and diffusion, and gas-liquid contactors (GLCs) which leverage two-phase dynamic mixing to supercharge the mass transfer of tritium.

The HEAT Lab’s tritium extraction research revisits gas-liquid contactors in a new decade, where significant advances in simulation technology allow us to quickly explore many deficiencies in previous designs. In theory GLCs should be capable of achieving more surface area than PAVs with small enough bubbles, but bubble coalescence has been a major challenge. Our lab has identified superior geometries that can do a much better job maximizing surface area and circulation, and are also interested in the spray regime (liquid in gas, rather than the bubble regime of gas in liquid) which remains mostly unexplored. Very little tritium extraction work has been done with FLiBe specifically, which is also a literature gap we hope to fill. We plan to explore these venues of improvement via both simulation and experiment.